The entire process of cycling pressurized water from the pump’s outlet side to the inlet/water tank for bypassing is a crucial job to do. And guess who’s in charge? A safety switch called an unloader valve.

The pressure washer unloader valve consists of a high tensile body, piston with seat stem and ball, washer, long spring, locknut cap, and so on.

This part basically helps in the prevention of any build-up by depressurizing the water during the time the pressure washer sits idle. So clearly, this is a big role to play. But several issues can cause hindrances in this process.

And perhaps that’s why you need a pressure washer unloader valve diagram, which I have put down below. Along with that, you also need an understanding of the mechanism. Don’t worry you’ll find that as well.

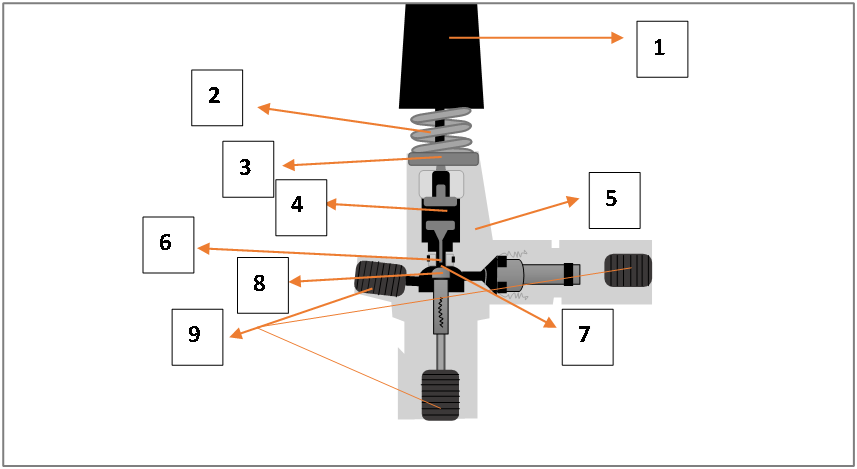

The Pressure Washer Unloader Valve Diagram!

Starting with pressure washer unloader valve location. Being a safety gear, the unloader valve is located on the pressure washer’s mouth (with a black cap on top) where the hose meets.

It’s tough to guess the ins and outs of the part. Not until now! Just look beneath to find the picture and its interpretation.

List Of Pressure Washer Unloader Valve Parts

Without wasting time, let me explain each component’s meaning of the above Pressure washer unloader valve parts diagram.

1 Stand for Lock Nut’s Cap

It’s simply a guard that hides two lock nuts (10 mm and 17 mm) and a couple of portions of ‘2’. This part not only ensures the protection of the metal surfaces against rust but also secures the desired pressure system during the flow of water.

2 Stand for Long Spring

Most of the time, this part contains a color coating that hides the metal surface and maximizes its lifespan against obstacles. It confirms the maximum mechanical pressure to divert the water flow.

3 Stand for Washer

Made out of metal, it simply holds other parts in their place and prevents them from coming out during the operation.

4 Stand for Inner Piston

It’s the main part that causes the force to expand and shift in a direction through continuous movement. This component stays in fixed place that helps move the high or low water pressure.

5 Stand for High Tensile Body

Although in the diagram, this might seem slightly less noticeable but it’s a shell that keeps the unloader valve inside. It’s a solid body built out of forged brass

6 Stand for Piston Stem

As you can see in the diagram, it’s a tiny rod-like part that meets the inner piston at the rear side. It simply goes up and down to make a path for the water of any pressure (high or low) to flow directly.

7 Stand for Piston Seat

This component stays in between the ‘6’ and ‘8’ which helps the upper part to simply sit on it without making huge metal-to-metal contact and damage.

8 Stand for Piston Ball

In the illustration above, this part is the round ball-like object that helps the piston to flow the water in a direction.

9 Stand for Inlet Ports (Optional)

It’s basically 3 ports that go in the left, right, and down directions. The left one is the inlet port that comes from the pump. Then again, the right one is the outlet port. Lastly, the below one is the bypass port.

Pressure Washer Unloader Valve Mechanism

A slight insight into how all these things work together should be helpful for whatever purpose you need the diagram for, that’s what I think. So here we go!

Now to understand how does a pressure washer unloader valve work you must have a sound knowledge of its purpose. Hopefully, that is already clear.

A pressure washer unloader works as a safety switch that can transfer pressurized water into a bypass. And it does that by simply cycling the water towards the inlet or water tank from the pump’s outlet side.

You can visualize the unloader as a relief valve. As there are different types of pressure washer unloader valves, it is going to get activated by one of the two factors:

- Once there’s a reduction in flow.

- Or if the pressure has increased.

You need to release the trigger gun for activating it. Once you do that, the spring and the ball check mechanism start working. It begins to send the water into the bypass.

Both of them also conduct the water flow diversion that starts from the spray nozzle. And then it is sent to an incessant cycle taking place between the pump system’s inlet side and outlet side.

As long as you don’t pull the wand trigger again, this shall keep going. Once you do pull it, the unloader flow actuation will turn off. Hence the water will now redirect toward the nozzle.

Frequently Asked Questions (FAQs)

Can you run the pressure washer without an unloader valve?

You can run a pressure washer without an unloader valve. But with the risk of crossing the PSI limitation that can cause permanent damage to the hoses, gun, and pump. As the unloader valve won’t be present to redirect the pressurized water and stop the buildup of pressure.

How do I know if my unloader valve is bad?

You can check the pressure washer unloader valve symptoms to confirm if it’s bad. The pump getting hot quickly and the engine needing more power are all big signs that there’s something wrong with the unloader valve. Engine noise, water leaks, and output pressure being inconsistent are all valid signs to watch out for.

Wrapping Up

And with that being said I am close to the end of this guide. Hopefully, the provided pressure washer unloader valve diagram will be able to help you in whatever matter you need it for.

Also, if it’s something you have not tried before, understand the mechanism, and even go through the guides that discuss the process in depth to make sure you don’t damage anything out of ignorance.

Good Luck!