It’s not always convenient to take every little problem you are facing with a Deere l120 to a mechanic and basically spend those extra bucks.

What is however pretty convenient and could be money saving, finding out the issues yourself and trying to fix those by learning solutions. Not going to lie, this route does take time and effort. But what it does not take is a big portion from your wallet.

The belts have to be a significant part of the Deere l120. And to solve issues with it, a John Deere l120 belt diagram will help. So, we wanted to start there. Also, it will seriously help if you are trying to put a belt on the Deere l120.

To put a belt on a john Deere l120 automatic, you need to have the lift lever to the lowest position, have a wrench on the sheave nut of the idler, bring the idler sheave onto the tractor front, and have the belt tension on hold. Then you put the belt on the drive sheave and afterward release the idler sheave so that there’s tension applied to the installed belt.

Apart from the diagram, we will try to help you find solutions to the most common issues. And give you some guidelines on procedures such as replacement and adjustments of the belt that will come in use during the troubleshooting. Enjoy!

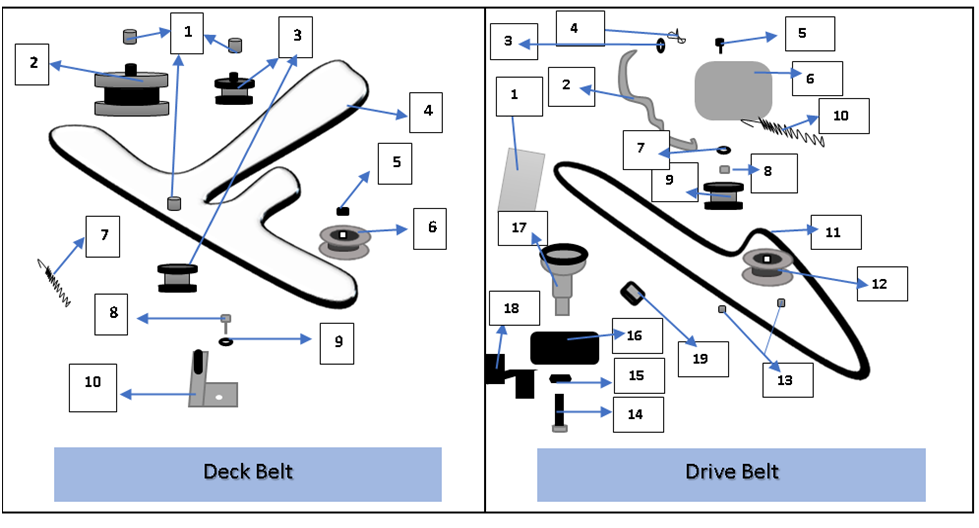

The John Deere L120 Belt Diagram With Explanation

The lawn tractor needs a belt to operate properly. In case you are searching for the diagram of the John Decree L120 belt, here’s the highlighted illustration.

Parts Detail In The John Deere L120 Deck Belt Diagram

It is located beneath the John Deere L120 tractor. As you can see the diagram has tons of parts on the deck belt side, we’ll discuss each part so you can recognize them when doing repair jobs.

1 – Lock Nut (10 MM)

You’ll see 2 lock nuts in the picture where one will go on top of the deck idler pulley and another one will stick to the flat idler pulley. They are hexagonal in shape and made with stainless steel mostly.

2 – Deck Idler Pulley

To direction the drive belt in the right curve and ensure tension, this part does a great job. It is slightly bigger than the flat idler pulley.

3 – Flat Idler Pulley

It is used to shift the fixed center roller driver with the deck belt. Plus, this is used to take care of the extra length of the belt. To locate this, look at the black idler pulley one.

4 – Deck Belt

It’s an essential part to move the mulching blades to chop the grasses through the connection of the crankshaft to the tractor. Most of the time, the deck belt comes in 1/2” width and 139” length to ensure proper fit.

5 – Spindle Nut

This part is a different type of nut that fits securely and safely to ensure a proper seal. It sits on top of the spindle drive sheave.

6 – Spindle Drive Sheave

It looks like a CD disk that is black in shade. This part just ensures to support the deck belt to offer better tension to move well.

7 – Tightener Spring

This stays on the idle or pulley in most cases. It lets you adjust the tension level of the deck belt when needed.

8 – Flanged Screw

Look like an ordinary screw, this is just used on the frame to ensure proper fitting. It sits on the idler arm to ensure a proper seal.

9 – Bushing

This part goes inside the flanged screw to ensure no rust or imbalance. Most of the time, it is made out of rubber material.

10 – Idler Arm

It is simply a bracket or frame that gives support to secure the belt on the lawn tractor so that it rotates. This part holds tons of holes to fit the screws.

Parts Detail In The John Deere L120 Drive Belt Diagram

The drive belt in the John Deere L120 is located above the deck mechanism. It has tons of parts which you need to get introduced.

1 – Support Bracket

It’s a big supporting bracket that holds the screws to protect the fitting of the drive belt.

2 – Rod

This part sits on the top areas of the drive belt. It’s just a usual rod that is medium in size.

3 – Washer

Made out of rubber, this is an ordinary washer that sits to ensure a tight seal.

4 – Cotter Pin

Being a highly versatile and reliable pin, this part ensures good locking of two components.

5 – Bolt

This part is a fitting gear that uses on top of the arm to hold the part and secure it to the tractor frame.

6 – Arm

It’s another bracket that sits on top of the drive belt. This also holds holes to insert the screw.

7 – Bushing

This part is solid protection to ensure the metal-to-metal connection between the arm and lock nut.

8 – Lock Nut

It is a part that holds the bolt, arm, and bushing in the proper tension. You only need to use a wrench to fit it.

9 – Idler

This is a solid part that ensures proper tension and movement of the drive belt. It sits on the edge of the drive belt to support.

10 – Idler Spring

It’s similar to the 7 no of the deck belt. The only difference is this part stay on top of the drive belt.

11 – Flat Drive Belt

This is a flat or transmission belt that connects the engine shaft to the input shaft. The John Deere L120 drive belt size is around 141-1/8” or 89” L (length) x 5/8” W (width).

12 – Idler

It’s a different type of idler that sits inside the drive belt to ensure stable movement and tension.

13 – Lock Nut

This part is similar to 8 no part of the deck belt. The only comparison point is it’s slightly smaller.

14 – Cap Screw

It’s a special kind of screw that holds the socket to fit inside and twists deeply. This part stick to the clutch.

15 – Lock Washer

You’ll see in the diagram it’s a thick washer that goes inside the cap screw to ensure no damage to the part.

16 – Clutch

It contains a center shaft and ensures giving the proper tension to secure the big idler.

17 – Idler

This part contains a connector at the end to fit inside the clutch and fit through the cap screw.

18 – Strap

It’s another part that looks similar to the bracket. This is square in shape and holds holes that sit on the tractor frames.

19 – Grommet

This is black in shade and tiny in real life. It is built out of resilient rubber to ensure the tension and stays tight in place.

Frequently Asked Questions (FAQs)

What is the john Deere l120 belt part number?

The john Deere l120 belt part number is GX20305. You can use this number for finding a replacement belt.

How to adjust a John Deere drive belt?

To adjust the drive belt, you must follow the manual instructed method. However, typically it requires loosening the transmission drive belt idler arm’s middle bolt to loosen it and then adjusting it using a combination wrench and socket wrench.

What happens if you install the belt incorrectly?

A number of issues can happen to john Deere l120. But the most significant issue to show up would be the discharge chute plugged.

What can lead to poor belt tension?

An improper belt installation can cause the belt to work with poor tension. And it’s a serious problem that can make the other components fail at any time.

Wrapping Up

And there you have it! From the john Deere l120 belt diagram to the explanation of common issues to guide for handling the belt, we have tried to bring you the most comprehensive guide you’ll ever find in this matter.

We hope it was helpful! But if you still feel stuck with unresolved confusion due to much serious trouble going on with the belt, don’t delay contacting a professional.

Often that’s the best way to make sure your machine is running smoothly and also to ensure it does not get completely out of use.

We’ll be back with more soon, take care!

You Can Also Raed: