From conducting the whole seeding procedure of a new lawn to doing bug infestations treatments, there’s a lot your Scotts spreader helps you with.

And when there are issues with this tool, you need to be quick at finding what’s wrong and solving the problem.

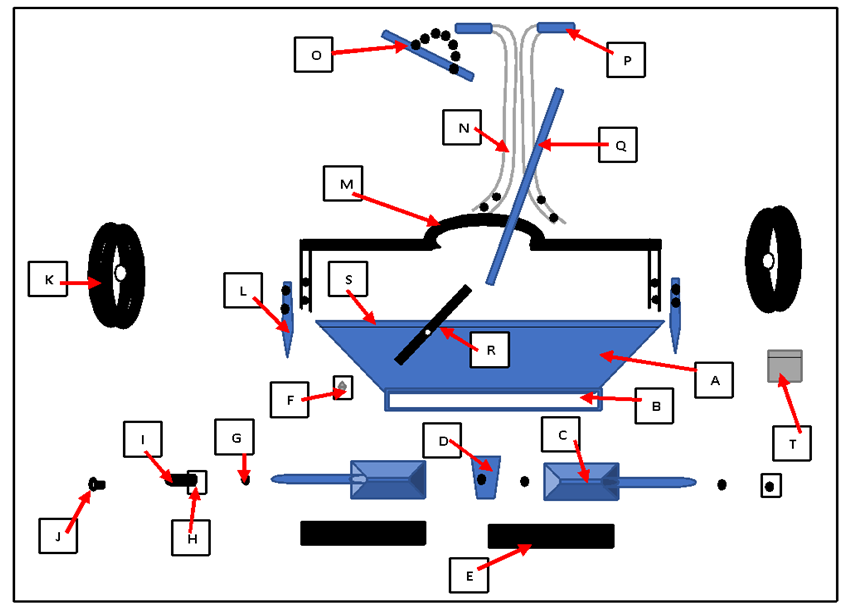

For that, a complete understanding of all the Scotts spreader parts could be necessary. And that’s where the Scotts spreader parts diagram enters the chat.

Keep On Reading…

Scotts Spreader Parts Diagram, Explanation, Common Issues, Maintenance Tricks & More

Today, let’s find out about the parts, talk about a few common Scotts spreader components issues and also explore the most workable maintenance habits that help in keeping these parts good for a while.

Next, we have the Scotts spreader parts list with a short explanation on each, hope it helps.

A is the Hopper Assembly

This is one of those Scotts spreader parts that directly work in composting and fertilizing by letting the spreader carry.

B is the Shutout Bar Assembly

There are two points in the spreader bar that is for load attaching. So that there’s even weight throughout the whole bar as well as wire rope slings. This helps in better lifting. To get seamless vertical hoists with the bars, there are also positioned attachment points.

C is the Agitator or Axle Assembly

The Scotts spreader parts agitator plays a key role in the efficiency of the spreading overall. As you see, proper agitation is an element that is most critical for that. This part basically makes sure the fertilizer is in the right mixture at all times inside the spreader.

D is the Bearing Support Assembly

This is one of the Scotts spreader parts that is basically a machine element. And its job is to constrain relative motion. So that there’s only preferable motion and less friction between parts that are constantly on the move.

E is the Agitator Baffle

These parts are responsible for minimizing any variation in the power draw of the agitator. Also, it helps in stabilizing the mixing flow pattern. The baffles are flat plate-shaped internals that works in the agitated vessels.

F is the End Hanger

To suspends any sort of fitting purpose, there’s a versatile solution called hangers. And this part basically related to it.

G is the Axle Grease Seal

There’s a need for sealing to retain grease inside the housing or case. And oil, dirt seal, or grease seal is used basically for that purpose.

Also Read: How To Fix A Scotts Broadcast Spreader? [A Complete Guide]

For the components that are stationary and moving, there can be spaces, in which the grease seals close. And so, the whole equipment never faces lubricant escapes.

H is the Plate Assembly – Bearing End

It is a part of the test unit and it’s a pretty important element. The proper distribution of load in axial pulls out, is what the part targets to accomplish.

I am the Grease Fitting

A part that works for feeding lubricants through a grease gun into the bearing, is what a grease fitting basically does. And once upon a time, this was a quite popular enhanced method used for moving parts lubrication.

J is the Axle Bearing

On each of the mounting ends of a live axle, you should find a device that is called axle bearing. And it exists to prevent any sort of resistance or wear while the spinning process.

K is the Wheel & Tire Assembly

There are many primary goals that the wheel and tire assembly have. But mostly it’s about load-supporting of the vehicle and traction transmission.

Also, for the braking forces, direction change or maintenance, and even road shock absorbing. Those are some of the major duties of this part.

L is Leg

The hopper and other accessories need to be in the right spot at all times. And that’s what the leg does, holds all of that in its designated spots.

M is Handle Brace

There are floor sweeps that d need some additional reinforcement. And the handle brace can provide that as it made pretty heavy duty. There’s less twist or turning because of the stabilization that this part provides.

N – Upper Handle Assembly

This is one of the parts of Scotts spreader that exists on both left and right sides. And it basically allows maneuvering and moving around of the whole gear to desired directions.

O is Chain Included Handle Lever Assembly

In case of accidental release of the handle by the operator, this part makes sure the spinning stops.

P is Handle Grip

For ensuring the operator has enough grip and tight hold, this part exists.

Q is Control Tube & R is the Control Tube Brace

The control cable needs some safe guiding. And the control tube is that protective sheath providing the guide. And it basically attaches the radiographic exposure device and control drive mechanism.

While the bracing system exists as a secondary mechanism that is the bridge structure’s must-have element. It helps in stabilization.

S is the Hopper Handle

For throwing the fertilizer out, there’s a part in the hopper called the front holder.

T is the Fastener Package

Two objects affixing together through a device is called a fastener. And it is something people use for joints that do not need to be permanent. So, you can remove or dismantle those and there will be no harm done to the components that take part in the joining.

Common Issues with Scotts Spreader Parts – And Ways to Fix Those

A few issues that you could be facing with the components of Scotts spreader are what we would like to address in this section. Of course, with some idea on how to solve those. Enjoy!

No Rotation Suddenly

If you suddenly notice that the spreader is no more rotating like before or has absolutely stopped rotation, then the most probable culprit is a clog. And that happens due to dirt getting accumulated.

You will require disabling using a tiny nose plier. Use water to clean and extract. You can also submerge the basket part in vinegar water for the whole night. And this should solve the problem.

Range Getting Lost

Now there can be a range loss issue with the spreader. And you just need to know that the nozzle and operating pressure are the in-charge of range duties.

To solve this, you need to repair the parts that conduct spreading. Don’t forget to clean the filter as well. This can also be due to a clog again.

Does Not Turn On

Another common spreader problem is the unit not turning on. And this can be because of the stuck wheel that is no more rotating. You will need to disassemble the wheels first. Then drill a hole to insert a pin. And this should make the spreader turn on without issues afterward.

Spreader Lock Issue

In this case, you require doing a complete checkup on wheels, nuts, and bolts. And similar parts. Make sure none of those are locked. In case they are, you need to lubricate those parts. And this shall allow wheel spinning freely. Make sure you also check the inflation of the tire.

The calibration Issue

At times, you may witness weak outcomes due to improper adjustments to the calibration power. The first thing to do in this case is to check the fertilizer amount.

You want to set the amount and mark the area as well. Proceed with the right settings to calibrate the spreader properly.

Maintenance Tips for Scotts Spreader Parts

Frequently Asked Questions (FAQs)

Where else can I find the spreader settings?

You should be able to find the settings on the information page provided by the manufacturer. You can visit the official site and there should be details and user segments including the details on the settings.

Are Scotts spreaders any good?

Yes. Most users have shared positive feelings about the spreaders provided by Scotts. The good models will be able to give you great coverage and also a good enough spread pattern with accuracy.

What do the numbers mean on Scott’s rotary spreader?

The numbers that you see actually represent the frizzler’s amount that can be used for a specified sq-ft area.

What setting should I set my Scotts spreader?

There are a few tips that can help in determining the settings of the spreader. First of all, you want to have enough for covering a thousand square feet of area. And then start with a low setting in the spreader.

Test spreading on 50×20 square ft area. Now if there’s leftover material, then the setting should be increased. However, in the other case, you need to decrease the setting. There’s no scientifically proven technique to this, but the tip discussed helps.

How to use Scotts spreader?

You want to check the bag’s backside for application detail. And also note the spreading dial setting for setting the one in the spreader. Use the right product to fill the hopper and start from the lawn’s perimeter.

Then gradually go towards all areas in the yard. You want to apply straight lines that go back and forth. For even coverage, you need to pass overlap. If there are materials left, put those back in the bag for later use. You also need to sweep the strayed material out from the lawn. And that’s it!

Wrap Up

And that was the Scotts spreader parts diagram with the explanation as well as much more information we believe will help you.

Now there’s no doubt that the spreader is one essential tool to have no matter if you own a small or big lawn.

And once you do own one, it’s important to make sure the spreader is in optimal condition to give the most use out of it. So, whenever there’s a need for repair, don’t delay it. The same goes for maintenance, keep it in your routine.